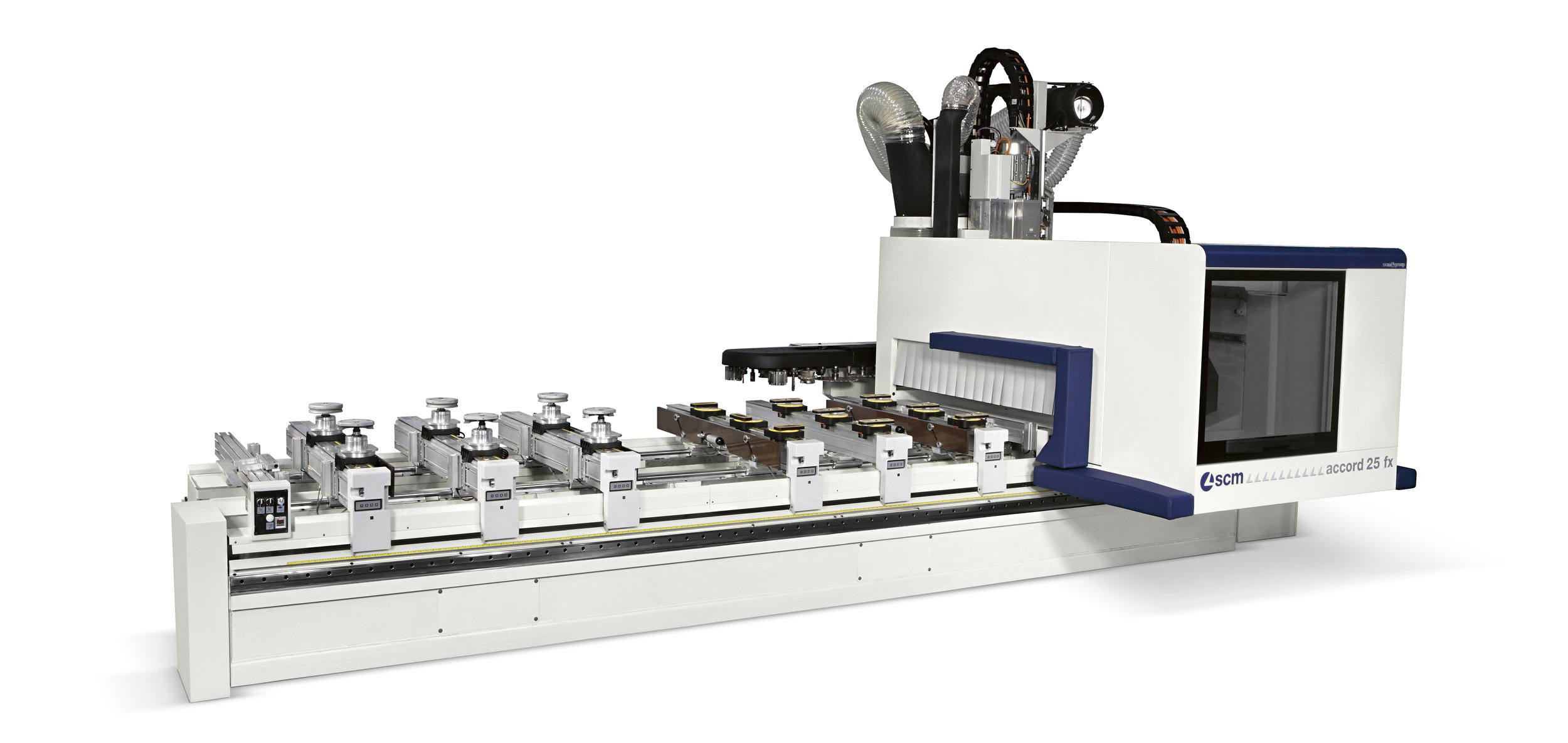

CNC Machining centre providing utmost performance with minimum investment.

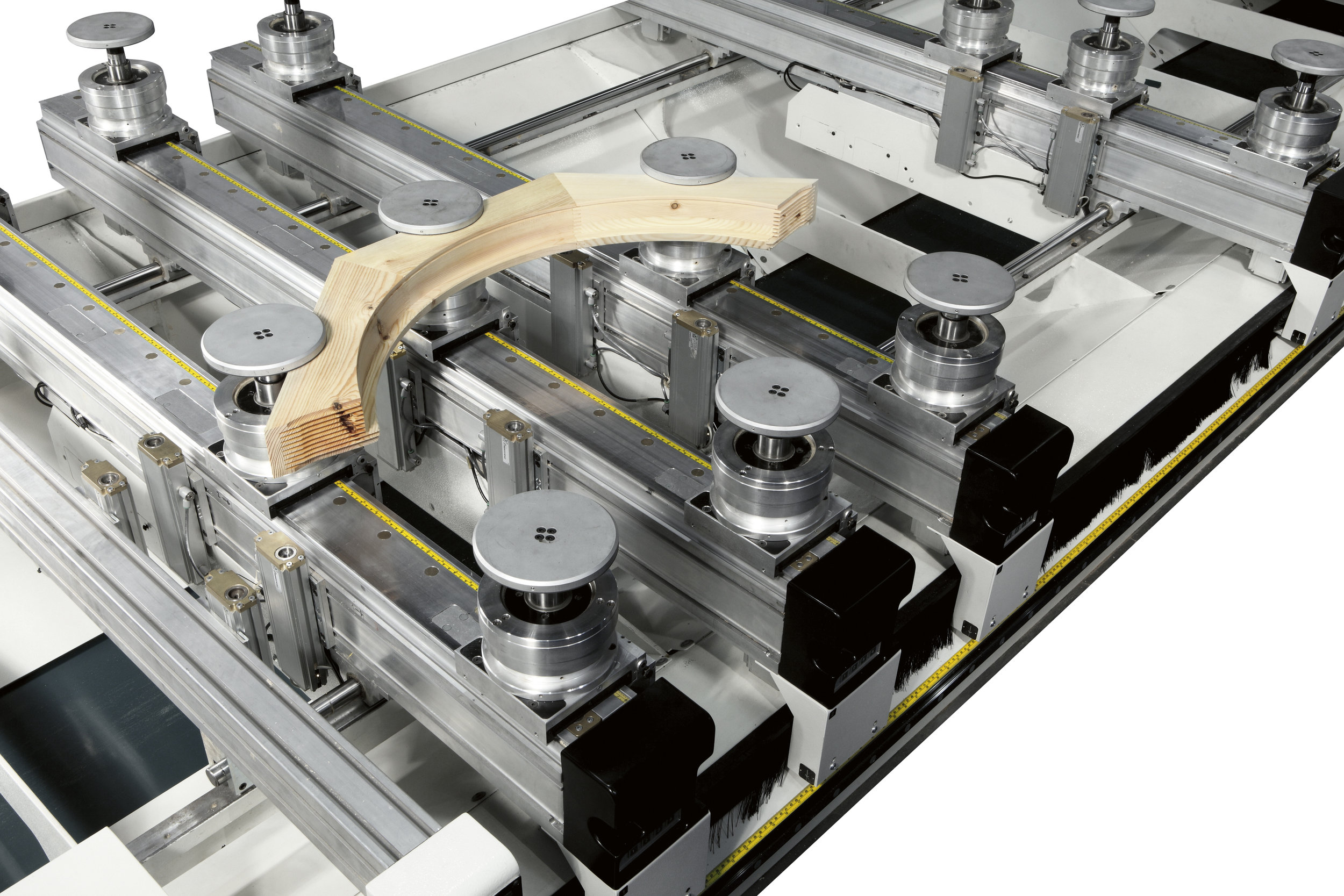

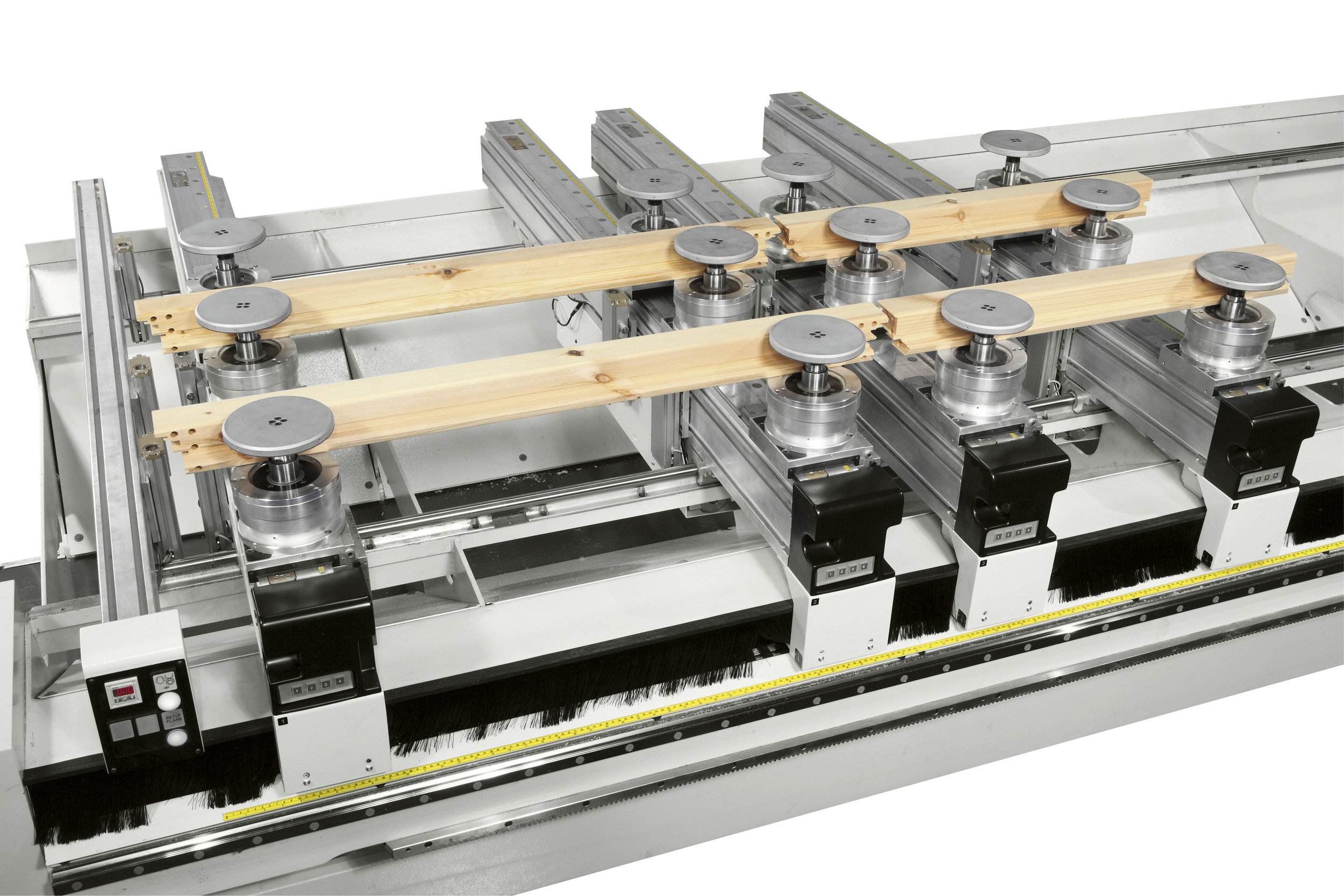

Designed to meet the needs of small and medium-sized companies, it combines state of the art technology with extreme ease of use for flexible productions of doors, windows, stairs, solid wood parts and for machining wooden and extra-wooden panels: plastic, composites, resins and light alloys.

ADVANTAGES

VARIED PRODUCTION

Possibility to produce various types of productsthanks to the increased Z-axial stroke up to 250 mm and 44 tools always available in the machine, guaranteeing fast tooling time and the machining of many different profiles. The new chain magazine TRC 32 lodging saw blades up to 350 mm diameter. It is fitted onto the mobile gantry, allowing pendulum machining with any type of tools.

ERGONOMICS AND SAFETY

The new safety system “Pro Speed” with horizontal photocells and new bumpers on the mobile protection (SCM patent), marries maximum accessibility to the work table and safety for the operator in the workpiece loading/unloading operations, whilst maximum speed and productivity are reached during machining.

SMART PROGRAMMING

Thanks to the Xilog Maestro software suite developed by SCM, programming is easy, intuitive and effective.

- Maestro 3D allows the programming and 5-axes machining of three dimensional surfaces.

- Maestro WD, developed specifically for the production of door and window frames, allows users to design starting from the architectural light to the individual frame elements to be produced.

- The Maestro Pro View simulator provides clients with considerable advantages by previewing the actual machining to be carried out in the machine on the office PC, in order to eliminate any errors and collisions and calculate production times and costs.

SAV€NERGY, high performance and energy saving.