Saw-spindle moulder machine whose professional technical solutions adopted give it unrivalled performance and reliability.

ADVANTAGES

Unique in the world in its category! The cast iron saw unit with a rigid closed loop structure can accommodate a blade of max. 400 mm diameter (for si 400es and Nova si 40) with the scoring blade mounted, ensuring perfect and easy cutting of veneer panels and thick solid wood material. The saw blade uses 100% of the motor power, thanks to the scoring blade with an independent motor as standard. The rotation fulcrums of the saw unit have a 120 mm diameter and stand on steady crescent shaped rests that separate it from the base: a rigid reliable solution.

Unrivalled cutting finishing

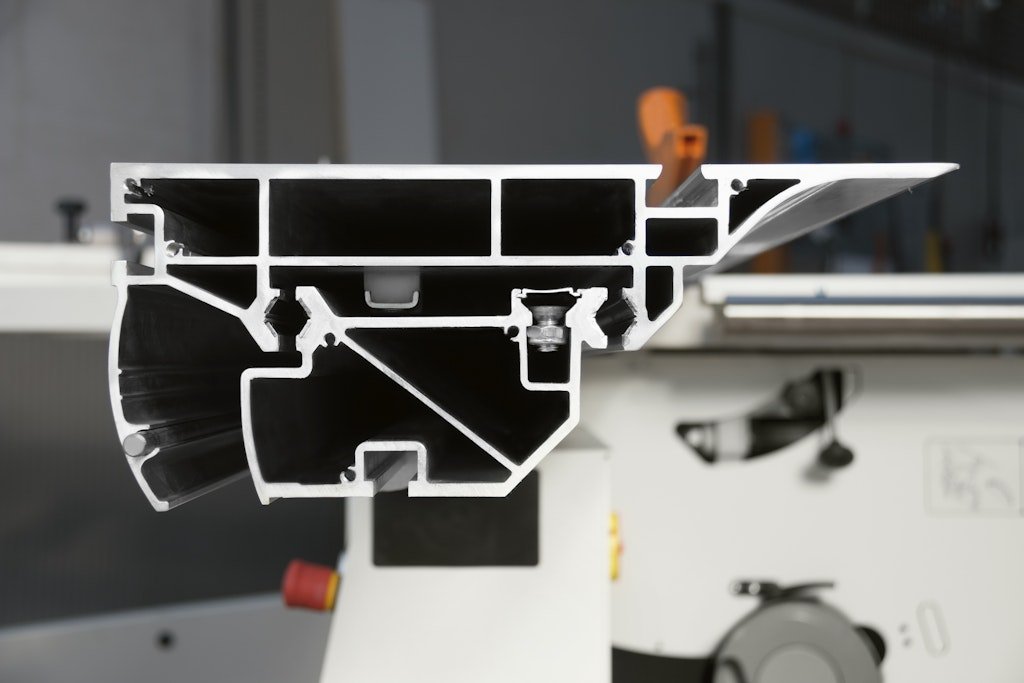

Optimal support also to larger pieces, with the sliding table 360 mm wide. Exceptional precision and smoothness: to secure the guides it is not used glue, since the thickness could affect sliding. They are secured with a procedure of aluminium riveting.

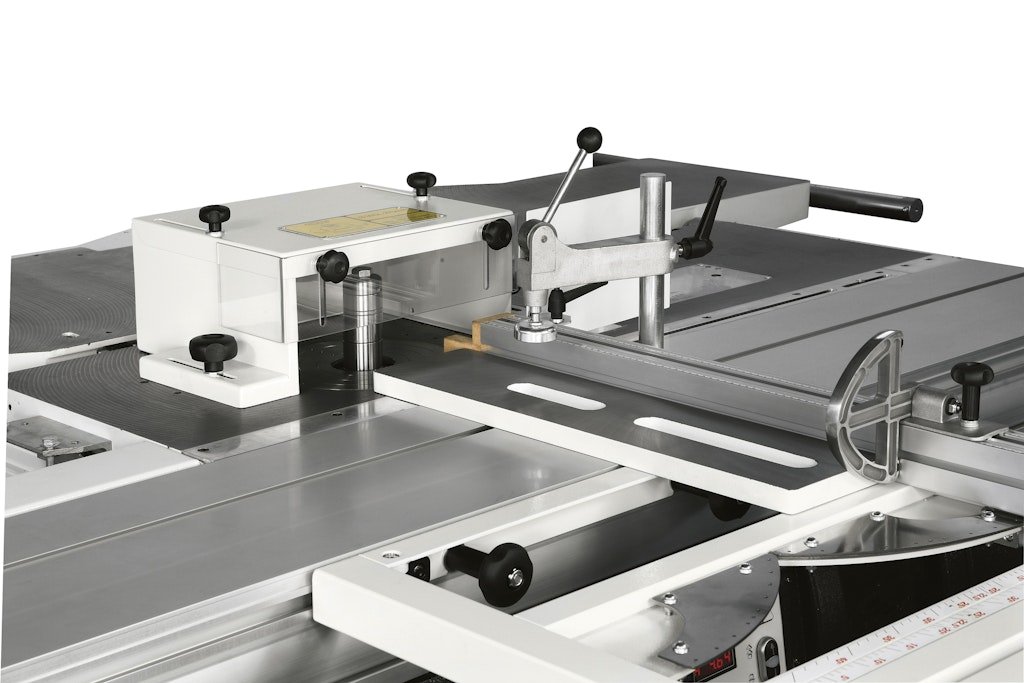

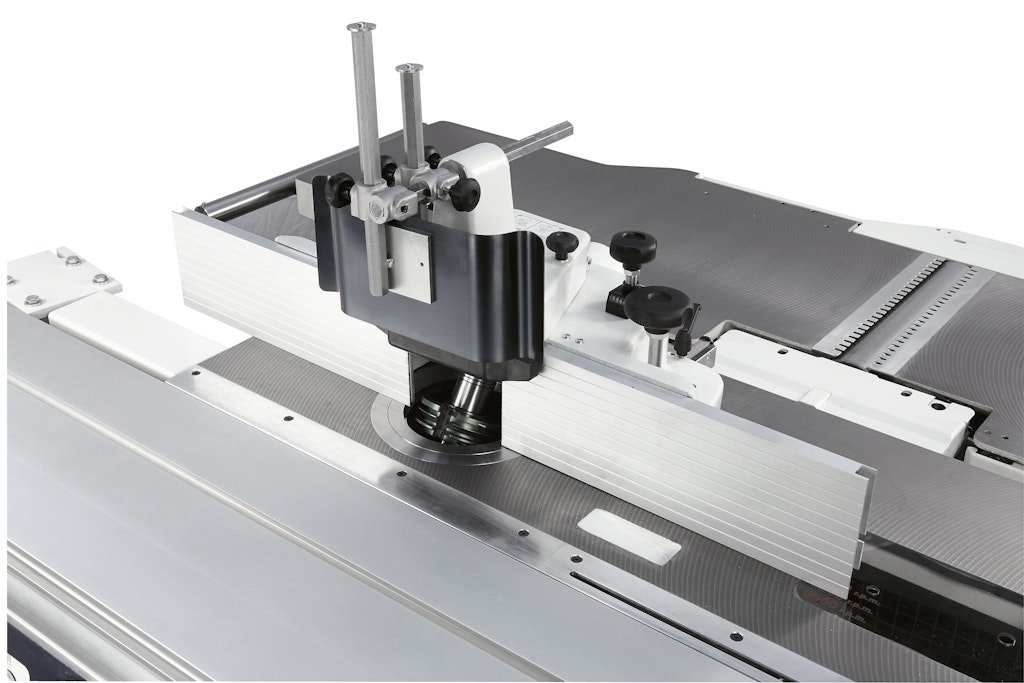

Unsurpassed moulding

Maximum stability and rigidity in all working conditions, thanks to a large spindle moulder column made entirely of cast iron. The 4 standard speed are ideal for any type of machining, from moulding to routing and tenoning, with the possibility to fit tools upto 320 mm of diameter (300 mm no CE).

Immediate control

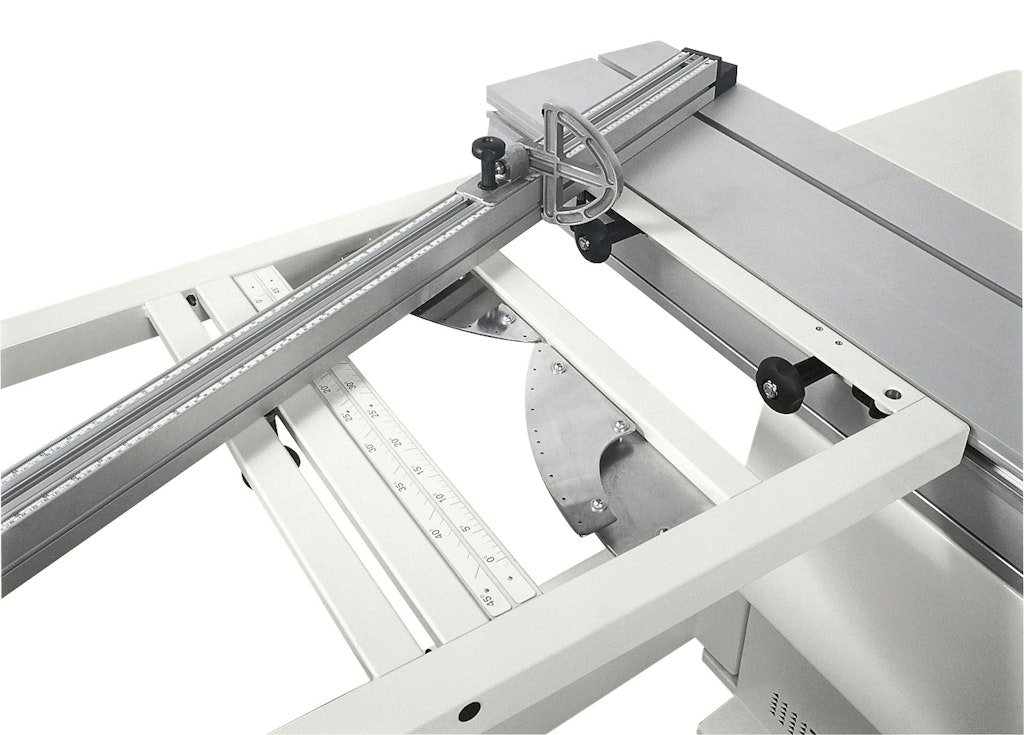

Panel loading is easy on the large squaring frame with an idle roller at the end. The telescopic squaring fence with the inclined metric scale and two reversible stops can be used to square panels measuring 3200 x 3200 mm and for miter cuts at up to 45° on both sides of the frame.

Max. sawblade diameter with scoring blade installed mm 350

Max. sawblade projection from table at 90°/45° mm 118 / 84

Cutting width on parallel fence (Rip capacity) mm 900 - 1270

Max. useful spindle length mm 125

Max. tool diameter when profiling mm 240

Three-phase motors kW 5

Max. squaring stroke of sliding table saw mm 2600