Band Saws

Full range of woodworking band resaws from 800mm to 900mm

Full range of woodworking bandsaws from 350mm to 900mm

Massive, high-precision, professional band saws for the D.I.Y. woodworkers and the carpentries.

Beam Saws

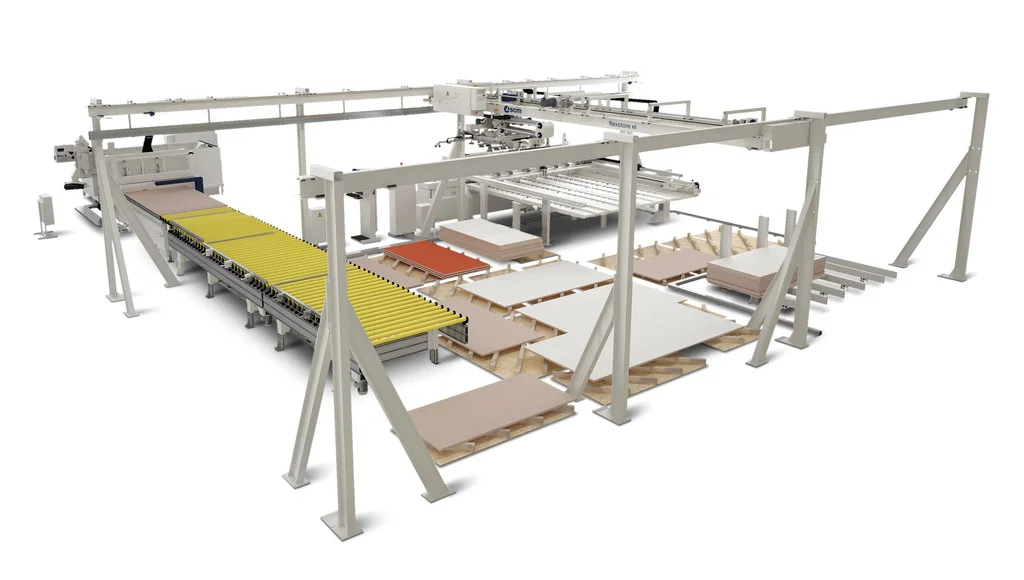

Functional and dynamic 3-axis automatic storage system for the panels management. It guarantees the optimisation of the material flow and machining time at low cost.

Storage cells composition with Prima and Impact beam saws. The machine has two side portal structures to support the main crossbeam. The machine is completely automatic and doesn't need any manual adjustment.

Single-blade beam saw controlled by PC/PLC control system, designed to cut solid wood panels or panel stacks and its products (chipboards, MDF panels, multilayer panels, plywood panels and fiber panels). The solution to integrate the beam saw inside a flexstore s or flexstore el storage.

Combination Machines

Saw-spindle moulder machine whose professional technical solutions adopted give it unrivalled performance and reliability.

Saw-spindle moulder machine for the demanding craftsmen and carpentries looking for flexibility and an “elite” quality finishing.

The advantages of an exclusive choice.

Buying a "L'invincibile" machine means you get a customized solution, thanks to experience, technical research and Italian creativity.

Surfacing-thicknessing machine, professional, massive and compact, for a high-flexible production; ideal for the demanding craftsman and carpentry.

Surfacing-thicknessing machine for the demanding craftsmen and carpentries, for a high-flexible production with an “elite” finishing.

Easy to use with rapidity combined with high productivity.

Great performance in a limited space.

Easy to use with rapidity combined with high productivity.

Great performance in a limited space.

Universal combined machine with all minimax quality, at the most affordable price, ideal for demanding hobbyists and crafts woodworking workshops.

Universal combined machine with all minimax quality, at the most affordable price, ideal for demanding hobbyists and crafts woodworking workshops.

Universal combined machine with all minimax quality, at the most affordable price, ideal for demanding hobbyists and crafts woodworking workshops.

Universal combined machine with all minimax quality, at the most affordable price, ideal for demanding hobbyists and crafts woodworking workshops.

Surfacing-thicknessing machine for the demanding craftsmen and carpentries, for a high-flexible production with an “elite” finishing.

The surfacing-thicknesser planer powerful and user friendly, for D.I.Y. woodworkers and craftsmen workshops.

Versatile and compact universal combined machine with the more advanced technological solutions for precision, reliability and safety.

The saw-spindle moulder for D.I.Y. woodworkers and craftsmen workshops essential, practical and with the best price/performances ratio.

The surfacing-thicknessing machine for the D.I.Y. woodworkers and the craftsmen joineries.

Copy Router

ONE-SPINDLE COPY ROUTER

Used for cutting appropriate slots on aluminium and plastic profiles

ONE-SPINDLE COPY ROUTER

- Suitable for passing workings.

- Manual working cycle.

CNC - ALUMINIUM EXTRUSION

3 AXIS CNC + 1 AXES PNEUMATICALLY MANAGED FLOOR-TYPE VERTICAL-SPINDLE MACHINING CENTRE.

Vertical spindle 5 axis CNC machining centre designed to work on extruded aluminium, light alloy, PVC and light steel materials.

Floor-type vertical spindle machining centre with 4 axis controlled by CNC, able to work on extruded

aluminium, light alloys, PVC and iron.

CNC - DRILLING & ROUTING

Machines ‘R’ Us now offer a range of Nanxing machines for the New Zealand market. Talk to our sales or visit our showroom to find out more.

CNC Machining centre providing utmost performance with minimum investment.

Designed to meet the needs of small and medium-sized companies, it combines state of the art technology with extreme ease of use for flexible productions of doors, windows, stairs, solid wood parts and for machining wooden and extra-wooden panels: plastic, composites, resins and light alloys.

This highly modular machining centre provides answers to all the problems associated with woodworking and with advanced materials processing.

Just a few clicks to design and manufacture pieces of any shape, the machine is run by the Suite Maestro which has specific modules for every production cycle.

Unique on the market in having an unrivalled price-performance ratio, it can be configured according to the customer’s needs and investment plan.

This highly modular machining centre provides answers to all the problems associated with woodworking and with advanced materials processing.

Just a few clicks to design and manufacture pieces of any shape, the machine is run by the Suite Maestro which has specific modules for every production cycle.

Unique on the market in having an unrivalled price-performance ratio, it can be configured according to the customer’s needs and investment plan.

CNC - NESTING

Machines ‘R’ Us now offer a range of Nanxing machines for the New Zealand market. Talk to our sales or visit our showroom to find out more.

The new generation of Nesting CNC machining centres meets the needs of a market increasingly oriented towards flexible and batch-1 production, combining excellent performance, maximum configurability with increased flexibility and productivity.

Machining centre designed and engineered for machining wood, plastics and non-ferrous metals.

Due to the unique design and PRO-SPACE safety systems, it requires less floor space and can be operated from all sides for material handling of smaller components.

Machining centre designed and engineered for machining wood, plastics and non-ferrous metals.

Due to the unique design and PRO-SPACE safety systems, it requires less floor space and can be operated from all sides for material handling of smaller components.

CNC - TIMBER CONSTRUCTION

Moving gantry machining centre with 5 interpolated axes. The CMS solution for precision working on very large pieces, such as curved beams and prefab walls.

Oikos is a compact machining centre with 6 axes, ideal for machining structural beams and modular wall parts in wood for the building industry.

It provides companies operating in the sector with a highly innovative solution to meet any demand from the constantly evolving market. Oikos is a compact machining centre with 6 axes, ideal for machining structural beams and modular wall parts in wood for the building industry.

It provides companies operating in the sector with a highly innovative solution to meet any demand from the constantly evolving market.

Area is the innovative CNC 5-Axis Machining centre with a mobile bridge structure and modular composition for machining big timber construction elements, such as CLT panels for walls, straight and curved structural beams. It allows machining of elements up to 4,5 m wide and 50 m long.

Dust Extractors

Trupro range of shaving extractors, available in single, twin, three and four bag arrangements.

The vf clean air dust extractors are specially designed to work in the woodworking shops, guaranteeing a level of dust emissions lower than 0.1 mg / m3.

Thanks to their compact design and the possibility to be connected to more machines, they can fully substitute the standard centralized exhaust system.

SCM range of shaving extractors, available in single, twin, three and four bag arrangements.

HOT-MELT EDGE BANDERS

Machines ‘R’ Us now offer a range of Nanxing machines for the New Zealand market. Talk to our sales or visit our showroom to find out more.

Panel return for edgebanding machine. Compact and economical panel return for high productivity and flexibility. A single operator is able to control the working process of the machine in maximum safety with minimum waste energy.

Continuous and versatile solutions for quality machining are the distinctive features of stefani kd.

All you would expect from an edge banding machine: the use of EVA and Polyurethane glue thanks to the SGP glue pot, machining units with electronic axes allowing the automatic set up for 2 different radii, infinite thin edges and solid wood up to 12 mm.

It is the ideal edge bander for all those companies that need to produce many panels for both small and large batch production.

Perfect joint line and versatility of use with the new SGP glue pot (Smart Glue Pot) and the pre-melting unit PU BOX L. Extraordinary level of finishing quality with the AirFusion technology that allows edgebanding without glue. Simply the perfect edge bander for all companies who require continuous production of a large number of panels even though they are all different from one to another.

High performance and versatility: olimpic k 560 is designed for companies requiring to process many panels per day even though they may be different from one to another. olimpic k 560 has several solutions that guarantee always the best machining on any panel type.

Versatility and high machining quality with the SCM olimpic k 360, the machine with the aim to be the new reference point in the market for entry level edge banders and complete with a rounding unit.

Compact and easy-to-use due to its advanced technological solutions designed to ensure optimal panel finishing. It is simply the perfect edge bander for companies who require continuous and high quality edge banding of panels even though they may be different from one to another.

The use of "multiedge" machining heads with electronic axes allows the machine to be set up automatically to machine panels with 2 different radii, solid wood and thin edges.

High level of inclusive equipment, advanced technological solutions and typical features from higher range models, guarantees the very best quality panels.

The features, coupled to its ease-of-use, makes the k 100 evo the perfect edge bander for small woodworking and panel processing companies.

High productivity edge bander with high quality performance. me 40, further enhanced compared to the previous version, with the new rounding unit that allows to obtain high quality finished products, without further processing, allowing a considerable saving of time and increasing ease of processing. It is confirmed as the most accessorizable machine in its technological range, with an excellent quality / price ratio. This edgebander increases productivity with the feed track of the panel brought to a speed of 9 m / min (the fastest in the minimax range) and guarantees high quality standards in processing thanks to the possibility of working with polyurethane glue, perform grooves, all being extremely easy to use.

Ease-of-use with all inclusive equipment: me 35, with gluing of the panel edge, also with edging solid wood strips up to 5 mm thickness, offers the “very best” performance in edge banders at this level.

The features, coupled to its ease-of-use, makes it the perfect edge bander for small woodworking, furniture and panel processing companies.

me 35. Further enhanced compared to its predecessor with the new end cutting-rounding unit. This new unit allows further processing, saving a substantial amount of time with an ease of processing.

This technological solution is unique in its category, where such operations are normally a feature of more expensive and higher level machinery.

Automatic edge bander with glue pot to edge band, with great flexibility, with melaminic edges, PVC and ABS up to 3 mm and wooden strips up to 5 mm. Machine for professional craftsmen and joineries.

Automatic edge bander with glue pot to edge band, with great flexibility, with melaminic edges, PVC and ABS up to 2 mm and wooden strips up to 5 mm. Machine for professional craftsmen and joineries.

End Mills

SINGLE SPINDLE END MILLING MACHINE

- Pneumatic cutter-head feed.

- Fast change of milling cutter sets.

SINGLE SPINDLE END MILLING MACHINE

- Integrated protection for the noise reduction and the elimination of any other risks.

- Pneumatic cutter-head feed.

- Fast change of milling cutter sets.

SINGLE SPINDLE END MILLING MACHINE

- Pneumatic cutter-head feed.

- Fast change of milling cutter sets.

Feeders

Formula power feed, best choice for safe and accurate processing of materials.

Equipped with inverter-driven motor with variable speed drive from 2 to 22 m/min.

Range of 3 or 4 wheeled power feed units

MITRE SAWS

Beading saw. The perfect compromise for accuracy toughness and maneuverability. Positive stops at 45, 30, 22 1/2 and 15 degrees on both sides of the rotation. A manual locking device for all the intermediate angles provides a great flexibility to this unit. The direct drive transmission and a powerful 1.75 HP induction motor make of the 1L 300 the ideal tool for heavy duty industrial usage.

SINGLE MITRE SAW WITH UPWARDS BLADE, Ø 450MM

- Manual rotation of the working table, up to 20° in both right and left direction.

- Quick positioning of the working table on pre‐selected angles (90°, 45°).

- Manual positioning at any intermediate angle, with pneumatic locking.

SINGLE HEAD MITRE SAW WITH DOWNWARD BLADE FEED, MANUALLY OPERATING Ø 400 MM.

DOUBLE MITRE SAW WITH ONE FIXED UNIT (LEFT) AND ONE MOVABLE UNIT, WITH BLADE DIAMETER 550 MM.

- Automatic positioning of the movable unit.

- Electronic positioning of the cutting units on any angle within 22,5° and 135°.

- Cutting length of 4000 mm or 5000 mm or 6000 mm.

- It is equipped with the system EC 700x.

DOUBLE MITRE SAW WITH ONE FIXED UNIT (LEFT) AND ONE MOVABLE UNIT, WITH BLADE DIAMETER 550 MM.

- Powered positioning of the mobile cutting unit

- Pneumatic tilting of the cutting heads on pre‐selected angles ( 90°, 45° or 22,5°)

- The intermediate degrees can be obtained by manually setting mechanical stops

- Cutting length of 4000 mm or 5000 mm or 6000 mm.

- It is equipped with the system EC 700x.

OPTIMISING STOP/PUSHER

Our simple and sophisticated solution for turning your manual machine into a semi-automatic resource by integrating an electronic stop which allows you to optimise the cutting process.

SawGear® is a highly portable automated saw fence that removes the need to set and adjust manual fences for length positioning and complex miter/angle cutting.

TigerStop® is an automated material pusher and stop gauge that will turn your existing machine into a lean manufacturing asset.

SawGear® is a highly portable automated saw fence that removes the need to set and adjust manual fences for length positioning and complex miter/angle cutting.

Radial Arm Saws

US12 was built to meet the needs of cutting large sections in combination with blade tilting and arm rotation.

US11 was built to meet the needs of cutting large sections in combination with blade tilting and arm rotation.

US10 was built to meet the needs of cutting large sections in combination with blade tilting and arm rotation.

US30 MX with integrated electronic stop, is designed to meet the needs of cutting large sections

US30 MX with integrated electronic stop, is designed to meet the needs of cutting large sections

RS900S with its cast iron frame offers versatility, cutting precision and functionality

for all different types of joinery material.

RS650S with its cast iron frame offers versatility, cutting precision and functionality

for all different types of joinery material.

RS750S with its cast iron frame offers versatility, cutting precision and functionality

for all different types of joinery material.

The radial saws of the formula line with an heavy cast-iron structure are available with 650, 750 and 900 mm cross-cut capacity.

Sliding Table Saws

High construction quality for reliability and safe performance.

The blade off system prevents any accidental contact with the blade thanks to an intelligent system that using smart sensors

Machines ‘R’ Us now offer a range of Nanxing machines for the New Zealand market. Talk to our sales or visit our showroom to find out more.

High construction quality for reliability and safe performance.

Buying a "class si x" machine means you get a customized solution, thanks to experience, technical research and Italian creativity.

The advantages of an exclusive choice.

Buying a "L'invincibile si 3" machine means you get a customized solution, thanks to experience, technical research and Italian creativity.

The advantages of an exclusive choice.

Buying a "L'invincibile six" machine means you get a customized solution, thanks to experience, technical research and Italian creativity.

High construction quality for reliability and safe performance.

Circular saw with ±46° double tilting.

Finally available at everybody’s reach. With powered and programmed sawblade movement available as standard.

It allows simultaneous use of a 400mm saw blade and 160mm scoring blade both for 90° cutting and ±46° tilted cutting, guaranteeing the maximum cutting height on veneered panels and solid wood.

High construction quality for reliability and safe performance.

The compact and highly precise circular saw with a low investment for DIY woodworkers and craftsmen

The precise, cost-effective and compact circular saw with tilting blade for the D.I.Y. woodworkers and the small joineries.

Solution Bundles

This highly modular machining centre provides answers to all the problems associated with door manufacturing. Unique on the market in having an unrivalled price-performance ratio, it can be configured according to the business needs and investment plan.

Spindle Moulders

Electronic-programmed spindle moulder with +/- 45,5° tilting spindle. The exclusive choice for your success. Buying a "L'invincibile ti 7" machine means you get a customised solution because it is the result of years of experience, technical research, Italian creativity.

Spindle moulder with +/- 45° tilting spindle. The best solution for every application. Precision and reliability with the the technological devices that guarantee reduced machine set up times, greater safety and ease-of-use.

Spindle moulder with fixed spindle. Guaranteed quality at your finger tips. Easy-to-use, productivity and efficency, flexibility.

Electronic-programmed spindle moulder/tenoner with +/- 45,5° tilting spindle

Surface Planers

The advantages of an exclusive choice.

Buying a "L'invincibile" machine means you get a customized solution, thanks to experience, technical research and Italian creativity.

Discover the "Xylent" cutterhead, available for this machine.

The best solution for every application.

Perfect surfaces, practical and safe, ergonomics.

Discover the "Xylent" cutterhead, available for this machine.

Surfacing planer for demanding craftsmen and carpentries who want more than the best!

Discover the "Xylent" cutterhead, available for this machine.

TENONING MACHINEs

Electronic-programmed spindle moulder/tenoner with +/- 45,5° tilting spindle

The exclusive scm tenoning machine with ISO 40 system which allows very high working rapidity and precision.

THICKNESSING PLANERS

The new minimax s 41es and s 52es thicknessing planer with 520 mm working width, professional, massive and compact, for a high-flexible production; ideal for the demanding craftsman and carpentry.

Discover the "Xylent" cutterhead, available for this machine.

The new minimax s 41es and s 52es thicknessing planer with 520 mm working width, professional, massive and compact, for a high-flexible production; ideal for the demanding craftsman and carpentry.

Discover the "Xylent" cutterhead, available for this machine.

The new minimax s 41es and s 52es thicknessing planer with 520 mm working width, professional, massive and compact, for a high-flexible production; ideal for the demanding craftsman and carpentry.

Discover the "Xylent" cutterhead, available for this machine.

The best solution for every application.

Easy and precise, practical design, a wider range of applications.

Discover the "Xylent" cutterhead, available for this machine.

The advantages of an exclusive choice.

Buying a "L'invincibile" machine means you get a customized solution, thanks to experience, technical research and Italian creativity.

THROUGHFEED MOULDERS

Automatic planer and throughfeed moulder up to 6 spindles, available in four compositions with possibility to preset the profiling on the top horizontal spindle (option)

Automatic planer and throughfeed moulder up to 6 spindles, available in four compositions with possibility to preset the profiling on the top horizontal spindle (option)

superset tm is the ideal automatic throughfeed moulder for producing large sized parts such as frames, semi-finished products for the building industry, beams and profiles for carpentry, wide parquet flooring and prismatic profiles in general. Designed to operate through various shifts per day, it comfortably handles small batches and large orders.

WAREHOUSE STORAGE SYSTEMS

Flexstore el, the automatic 3 axes storage, to optimize the handling of different panes designed for medium-large industries, it can be integrated in production lines for nesting and/or sizing cells, with a significant increase in productivity and considerable reduction of costs.

WASTE REDUCTION

Do you want to reliably process chipboard, hardwood and solid wood waste, bark or softwood into wood chips and briquette-ready material? Our VHZ series of compact and robust single-shaft shredders has been specifically designed to master these tasks. You’ll benefit from low operating costs thanks to energy-efficient drive technology, and in most usage scenarios, you can feed the collected materials directly to the machine without the need for additional feeding systems. Since the rotor turns particularly slowly, it makes little noise or dust during vertical feeding.

Do you want to reliably process chipboard, hardwood and solid wood waste, bark or softwood into wood chips and briquette-ready material? Our VHZ series of compact and robust single-shaft shredders has been specifically designed to master these tasks. You’ll benefit from low operating costs thanks to energy-efficient drive technology, and in most usage scenarios, you can feed the collected materials directly to the machine without the need for additional feeding systems. Since the rotor turns particularly slowly, it makes little noise or dust during vertical feeding.

Do you want to reliably process chipboard, hardwood and solid wood waste, bark or softwood into wood chips and briquette-ready material? Our VHZ series of compact and robust single-shaft shredders has been specifically designed to master these tasks. You’ll benefit from low operating costs thanks to energy-efficient drive technology, and in most usage scenarios, you can feed the collected materials directly to the machine without the need for additional feeding systems. Since the rotor turns particularly slowly, it makes little noise or dust during vertical feeding.

Do you want to reliably process chipboard, hardwood and solid wood waste, bark or softwood into wood chips and briquette-ready material? Our VHZ series of compact and robust single-shaft shredders has been specifically designed to master these tasks. You’ll benefit from low operating costs thanks to energy-efficient drive technology, and in most usage scenarios, you can feed the collected materials directly to the machine without the need for additional feeding systems. Since the rotor turns particularly slowly, it makes little noise or dust during vertical feeding.

Do you want to reliably process chipboard, hardwood and solid wood waste, bark or softwood into wood chips and briquette-ready material? Our VHZ series of compact and robust single-shaft shredders has been specifically designed to master these tasks. You’ll benefit from low operating costs thanks to energy-efficient drive technology, and in most usage scenarios, you can feed the collected materials directly to the machine without the need for additional feeding systems. Since the rotor turns particularly slowly, it makes little noise or dust during vertical feeding.

WIDE BELT SANDERs

Belt sander perfect for small woodworking companies.

It satisfies all solid wood calibrating and sanding requirements.

Belt sander perfect for small woodworking companies.

It satisfies all solid wood calibrating and sanding requirements.

Belt sander perfect for small woodworking companies.

It satisfies all solid wood calibrating and sanding requirements.

Maximum performance for companies increasing production. Designed for the medium to high industrial companies that require diversified machining, dmc sd 90 satisfies all calibrating and sanding requirements, by offering a wide range of technological solutions allowing the possibility of customizing the machines compositions.

Belt sander perfect for small woodworking companies.

It satisfies all solid wood calibrating and sanding requirements.

CNC AGGREGATES

Hiteco's HORIZONTAL LOW BORE aggregate is ideal for nesting operations with 3 exits for horizontal drilling. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's NOTCH BLADE aggregate is ideal for finishing and squaring internal wooden corners. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's NOTCH BLADE aggregate is ideal for finishing and squaring internal wooden corners. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's COPY aggregate is ideal for performing constant machining on irregular surfaces. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's DSIDE aggregate is ideal for drilling and milling from below avoiding overturning the machined piece in light alloys, plastic and stone. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's DSIDE aggregate is ideal for drilling and milling from below avoiding overturning the machined piece in light alloys, plastic and stone. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's DSIDE aggregate is ideal for drilling and milling from below avoiding overturning the machined piece in light alloys, plastic and stone. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's five-outputs VERTICAL BORE aggregate is ideal for performing multiple vertical drilling. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's six-outputs VERTICAL BORE aggregate is ideal for processing plastics. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's three / four outputs VERTICAL BORE aggregate is ideal for processing plastics. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's three-outputs VERTICAL BORE aggregate is ideal for drilling holes for hinge installations. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's THREE three-outputs aggregate is ideal for drilling and milling workpieces made of light alloys, plastic and stone. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

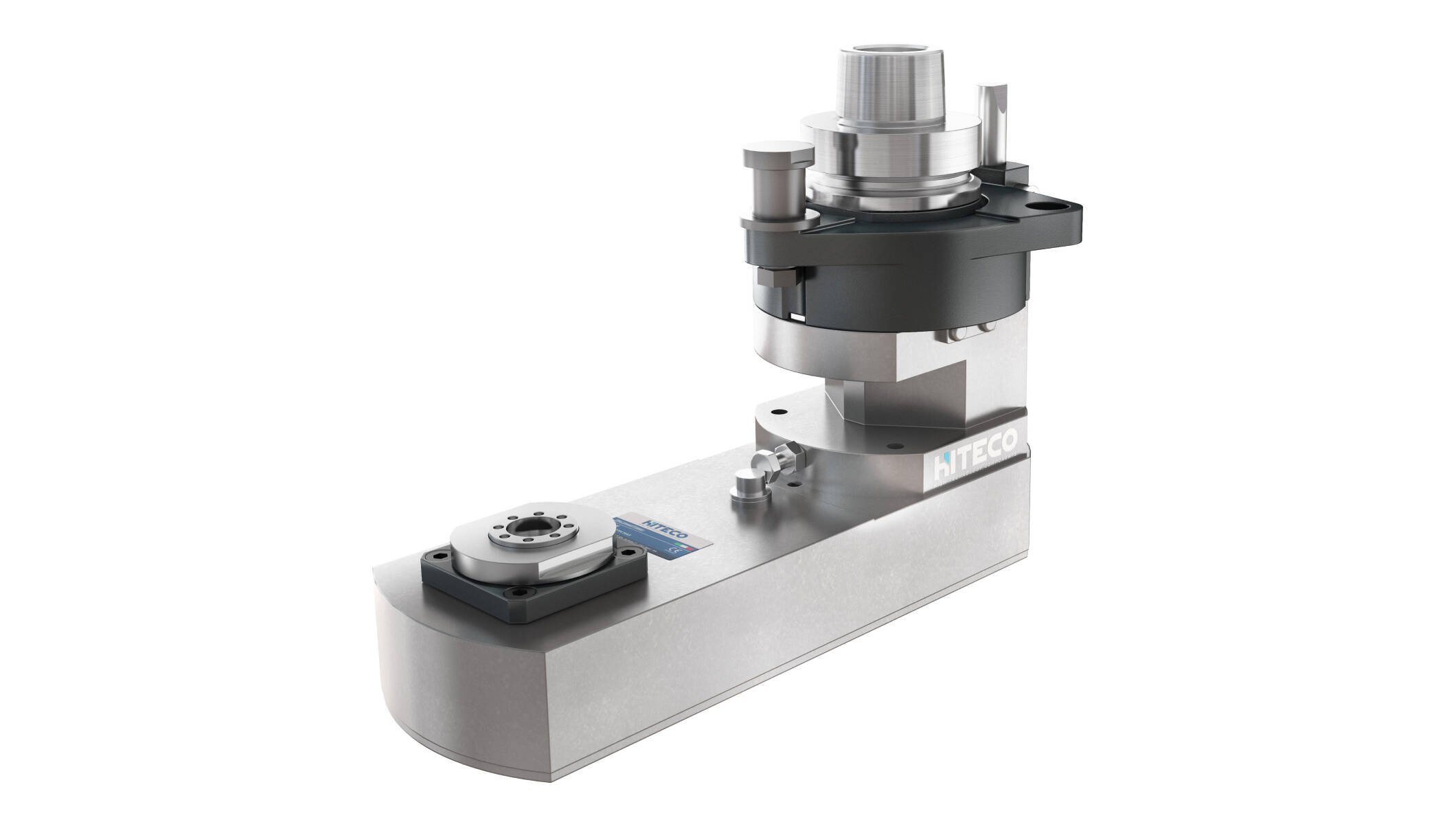

Hiteco's TILT BLADE aggregate is ideal for any wood, light alloy and plastic milling process. It is suitable for milling and drilling operations with tool inclination from 0 ° to 360 °. Great for drilling, milling and cutting. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's TILT BLADE aggregate is ideal for any wood, light alloy and plastic milling process. It is suitable for milling and drilling operations with tool inclination from 0 ° to 360 °. Great for drilling, milling and cutting. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's TILT BLADE aggregate is ideal for any wood, light alloy and plastic milling process. It is suitable for milling and drilling operations with tool inclination from 0 ° to 360 °. Great for drilling, milling and cutting. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's TILT BLADE aggregate is ideal for any wood, light alloy and plastic milling process. It is suitable for milling and drilling operations with tool inclination from 0 ° to 360 °. Great for drilling, milling and cutting. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's FOUR aggregate is ideal for drilling and milling with 4 tools of different sizes. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's FOUR aggregate is ideal for drilling and milling with 4 tools of different sizes. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's FOUR aggregate is ideal for drilling and milling with 4 tools of different sizes. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's One B350 aggregate is ideal use with glass and stone.

Hiteco's TWIN PRO dual output aggregate is ideal for any milling / drilling of wood, light alloys and plastics. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's TWIN G100 aggregate is ideal for milling, grinding and engraving glass and stone.

Hiteco's TWIN B250 aggregate is ideal for cutting glass and stone.

Hiteco's TWIN B210 aggregate is ideal for cutting, milling and engraving glass and stone.

Hiteco's TWIN aggregate is ideal for any milling / drilling of wood, light alloys and plastics. Suitable for processing any type of material and heavy loads. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's TWIN aggregate is ideal for any milling / drilling of wood, light alloys and plastics. Suitable for processing any type of material and heavy loads. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's TWIN aggregate is ideal for any milling / drilling of wood, light alloys and plastics. Suitable for processing any type of material and heavy loads. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's MULTIBLADE aggregate is ideal for woodworking with the simultaneous use of several blades. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's MULTIBLADE aggregate is ideal for woodworking with the simultaneous use of several blades. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.

Hiteco's MULTIBLADE aggregate is ideal for woodworking with the simultaneous use of several blades. Grease lubrication, ground gears in Carbon Lafer for high performance and guarantee of durability. Predisposition compatible with the main machine manufacturers.